-

Extended

Producer

ResponsibilityGet EPR ready with Wastepack -

find out how we can support

you today!MORE ON EPR

-

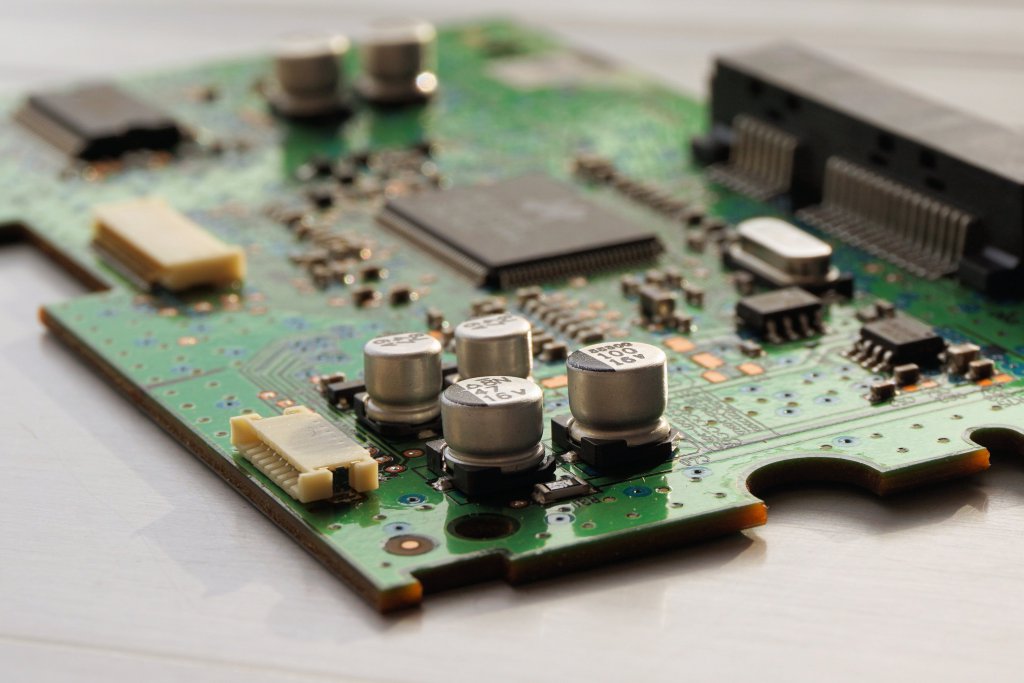

PLASTIC

PACKAGING

TAXAny business that manufactures or

imports plastic packaging in the

UK could be affected by the tax.

FIND OUT MORE

-

DATA SERVICEA complete data package

DATA SERVICEA complete data package

that saves you time and

provides accurate data

for your returnLEARN MORE

Packaging Regulations

Find out if your business is obligated under the Packaging Waste Regulations and required to register.

Extended Producer Responsibility (EPR)

A new EPR system will replace the current Packaging Waste Regulations in a phased implementation from 2023/4.

Plastic Packaging Tax

If you manufacture plastic packaging in the UK or import plastic packaging into the UK you could be affected by the Plastic Packaging Tax (PPT).

Industry News

See the latest news and insights in the Waste Packaging, and wider environmental compliance industry here.

Join us

We’ve been making compliance easier for our members for over two decades. How can we help you?